Laser Marking Systems: The Name of Power and Precision in Industrial Manufacturing

With the advancement of production technologies, marking systems have also undergone a significant evolution. Today, laser marking has become an integral part of industrial manufacturing. With its speed, precision, durability, and eco-friendly nature, laser marking offers solutions far beyond traditional methods. At Venox Teknoloji, we continue to shape the future of industry with our innovative products in this field.

So, what exactly is laser marking? What advantages does it offer? And what solutions do we provide at Venox Teknoloji in this area?

What is Laser Marking?

Laser marking is the process of permanently marking a surface using a laser beam. With this method, data such as serial numbers, barcodes, logos, and production dates can be applied with high precision to materials such as metal, plastic, glass, ceramic, and many others.

The key advantages of laser marking include:

- Contactless process: No damage to the part surface.

- High durability: The markings are long-lasting and cannot be erased.

- Fast and automation-compatible: Easily integrated into mass production lines.

- Eco-friendly: No chemicals used, no waste generated.

- Aesthetic results: Provides sharp, legible, and clear markings.

The Power of Laser Marking with Venox Teknoloji

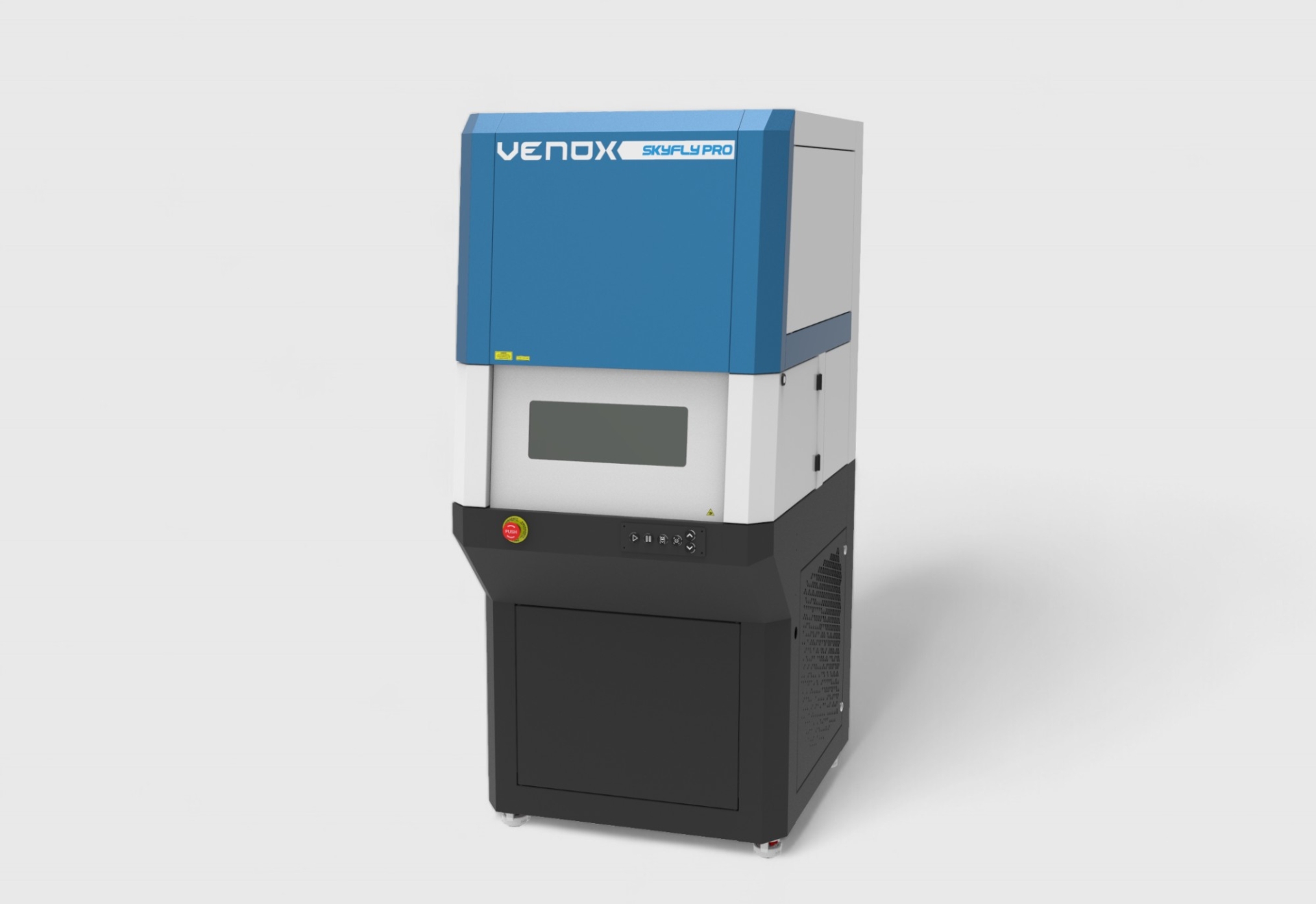

At Venox Teknoloji, we enhance your production processes by making them more efficient, faster, and more reliable with our laser marking systems specially developed for industrial needs. Our product portfolio includes Firefly Integrated, A Series, and W Series laser marking systems, each designed to meet different application needs.

Firefly Integrated

Firefly Integrated is a compact, powerful, and integrated laser marking system that can be easily adapted to modern production lines.

- Minimal space requirement thanks to its compact design

- High-speed, high-resolution marking

- Easy integration with PLC systems

- Long-term operation with advanced cooling technology

A Series

The A Series stands out with its modular design and versatility, offering a powerful laser marking solution for a wide range of applications.

- Superior marking quality on metal and plastic with fiber laser technology

- Easy focusing with automatic Z-axis

- Open platform for broad product compatibility

- User-friendly interface with robust software infrastructure

W Series

Developed for heavy industry and demanding production conditions, the W Series is designed for high durability and long-term performance.

- Industrial-grade housing and protection systems

- Deep and permanent marking with high-power laser output

- High performance even in dusty and humid environments

- Full compatibility with integrated automation systems

Why Venox Teknoloji?

- Local production and engineering: Our products are entirely designed and developed with local engineering.

- After-sales support: Fast technical service and spare parts supply throughout Turkey.

- Smart software integrations: Our products are compatible with ERP/MES systems.

- Sustainable technology: Our energy-efficient solutions minimize environmental impact.

Application Areas

Venox laser marking systems are effectively used in the following sectors:

- Automotive: Part numbering, serial coding

- Electronics: PCB marking

- Medical: Permanent marking of surgical instruments

- Defense industry: Marking of ammunition and equipment

- Food and packaging: Printing production dates and lot codes

- Jewelry: Engraving logos/serial numbers on precious metals

Shaping the Future with Laser

Laser marking is not just a marking method; it is also a strategic technology that supports processes such as quality control, traceability, and brand security. At Venox Teknoloji, we work to make the manufacturing world smarter, cleaner, and more efficient.

If you would like to learn more about our product range tailored to every need or to determine the most suitable laser marking system for your business, please feel free to contact us.

To explore all our products, visit www.venox.com.